CUSTOMIZED CONVENIENT EFFICIENT

PBA PROFILE DRILLING SYSTEM

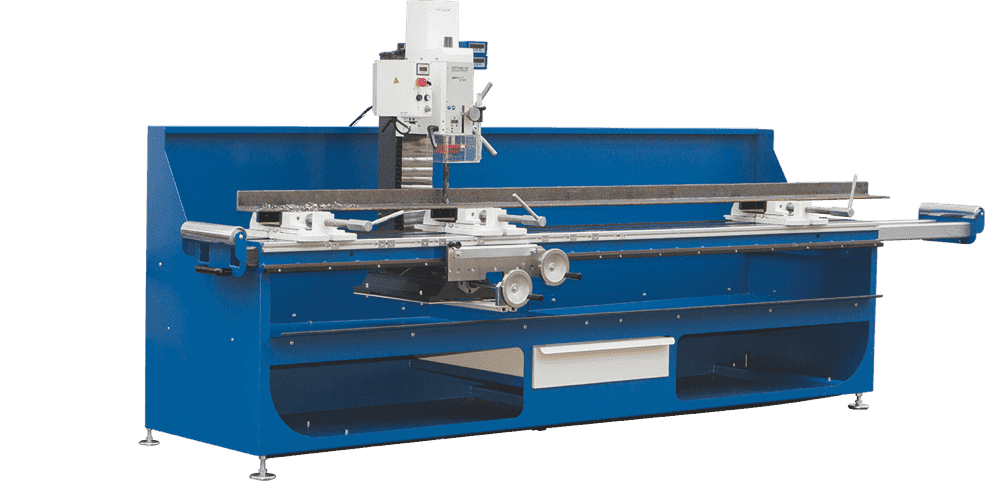

The RÖDER PBA PROFILE DRILLING SYSTEM is a compact and mobile drilling system for drilling profiles with the greatest possible efficiencies.

The ability to clamp very long workpieces and to accurately position drilling patterns eliminates time-consuming measurements, the scoring processes associated with high tolerances, in addition to center punching and manual positioning.

Positioning table with 3 jaw vices

Digital positioning display

Positioning rollers extendable in both directions

THE HIGHLIGHTS

The workpiece is readily clamped into the PBA PROFILE DRILLING SYSTEM. The tool then directly moves to and drills the desired dimensional points; the vice jaws are in this case continuously adjustable over the entire toolpath.

The dimensions are then directly read off on the digital position display. The home position can be set at any position. The absolute value display is in this case maintained and can be queried at any time.

Display accuracy: 0.1 mm.

Using the adjustable deadstops, workpieces can be repeatedly fabricated quickly and efficiently.

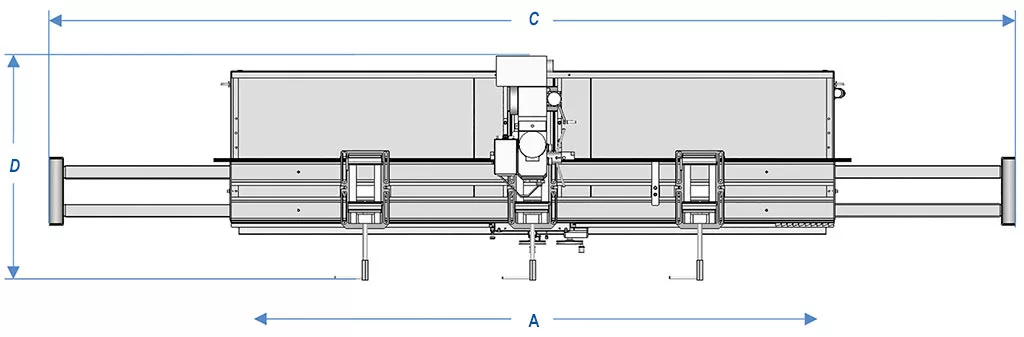

The positioning surface for the workpieces can be easily extended with the positioning rollers arranged on both sides.

Even angled bore holes are possible by tilting the drive head.

Your benefits

Straightforward operation

Short learning curve

Enormous time savings

Mobile applications

Very high repeatability

Supremely suited for mass production

Accurate boreholes in round tubes

Preserves the workpiece finish

PBA 3000 PROFILE DRILLING SYSTEM

WE CAN DO EVEN MORE

We will on request configure the PBA PROFILE DRILLING SYSTEMS based on the individual needs of our customers.

Systems can for example also be equipped with an NC controller, which can be used to generate, store, and repeatedly retrieve entire drill pattern programs. The associated controller is easy and user-friendly, thus reducing the learning curve to a minimum.

You can individually define the length of the system entirely to your needs.

Our objective is to give you the highest-possible quality standard.

In order to achieve this objective, we assemble all parts and components in-house and subject them to continuous quality control. Let us know about your needs and expectations. We will then work together with you to find the best solution for your specific application.

PBA PROFILE DRILLING SYSTEM WITH NC POSITION CONTROLLER

PBA 3000 PROFILE DRILLING SYSTEM POSITION CONTROLLER

ACCESSORIES

TECHNICAL DATA

| PROFIL DRILLING SYSTEM | PBA 3000 | PBA 6000 | ||

|---|---|---|---|---|

| Max. x axis length (A) | 3.000 | mm | 6.000 | mm |

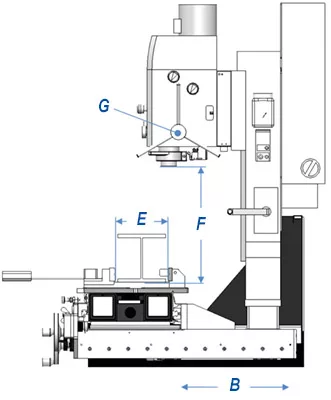

| Max. y axis working range (B) | 250 | mm | 250 | mm |

| Overall length, floorspace requirements (C) | 6.000 | mm | 8.820 | mm |

| Overall width, floorspace requirements (D) | 1.400 | mm | 1.400 | mm |

| Jaw vices, clamping range (E) | 220 | mm | 220 | mm |

| Number of jaw vices, standard | 3 | Stk. | 3 | units |

| Max. workpiece weight | 500 | kg | 500 | kg |

| DRILL DRIVE | KNUTH TSB 35 | OPTIMILL MH 35V | MAXION UNIMAX 3 T AV | |||

|---|---|---|---|---|---|---|

| Through passage, min. (F) | 200 | mm | 70 | mm | 280 | mm |

| Through passage, man. (F) | 630 | mm | 480 | mm | 500 | mm |

| Spindle stroke | 170 | mm | 80 | mm | 125 | mm |

| Drilling performance in steel | 30 | mm | 28 | mm | 26 | mm |

| Tapping performance in steel | M 20 | M 10 | M 16 | |||

| WerkzeugaufnahmeTool holder | MK 4 | BT 30 | MK 3 | |||

| Electrical connection / Motor | 400/1,2 | V/kW | 400/1,5 | V/kW | 400/1,5 | V/kW |

| Speed-controlled gearbox | 12 | Stages | 6 | Stages | 2 | Stages |

| Continuously adjustable speed setting | No | Yes | Yes | |||

| Drehzahlbereich bis max. | Max. speed range | min-1 | 3.260 | min-1 | 3.200 | min-1 |

| Tilting gearbox head | Yes | Yes | No |