MACHINING LONG PARTS MADE EASY.

PFZ 4000 CNC PROFILE MILLING CENTER

The RÖDER PFZ 4000 CNC PROFILE MILLING CENTER for accurately and efficiently machining long parts made of steel, stainless steel, and aluminum.

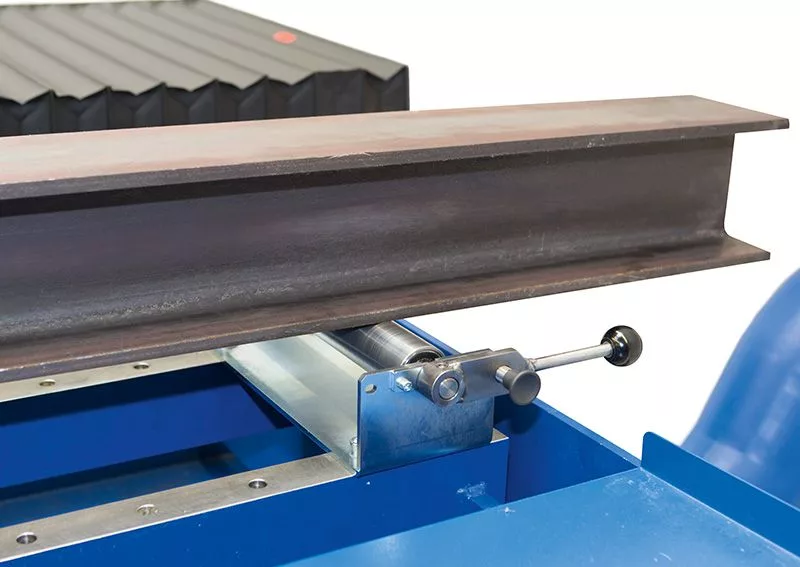

Due to its rugged design, the PFZ 4000 CNC is particularly suited for structural steel and mechanical engineering applications.

BEHIND THE SCENES

The machine bed of the PFZ 4000 CNC is made of a welded steel structure, giving it high stability and stiffness due to the specialized construction.

All guide axes are equipped with play-free guides and are driven by servomotors.A high-powered asynchronous motor drives the main spindle.

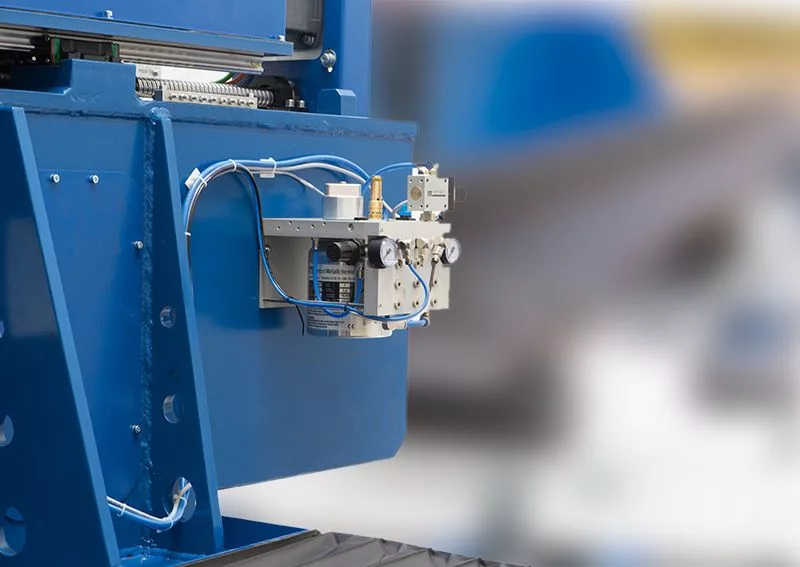

Tool cooling is achieved either with spray mist or emulsion (option). Internal coolant supply (ICS) can be selected optionally. The tool changer travels with the tool head as a particular advantage. Tool changes can as a result be made at any position, resulting in enormous time savings.

The open table with a readily accessible chip bin permits easy and efficient cleaning. A chip conveyor can be optionally integrated. The readily accessible jaw vices, spindle, and tooling permit the automatically adjustable safety shroud. A safety fence with light curtain guarantee maximum operator safety.

The professional Heidenhain TNC 620 CNC control supports functional and user-friendly production of graphics-supported drilling and milling cycles. As an equally convenient feature, the operator panel can be moved over the entire machine length.

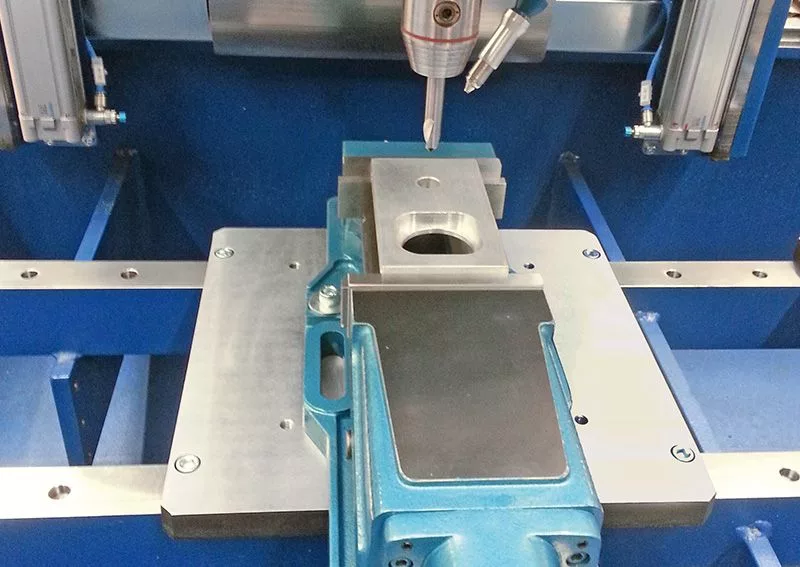

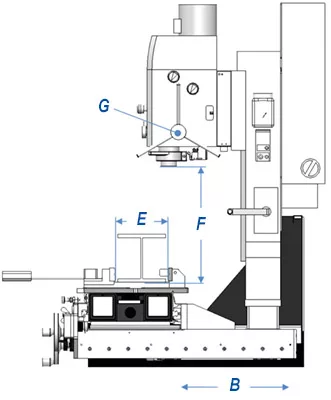

For workpiece clamping, customers can optionally choose between mechanical or hydraulic jaw vices or a T-slot plate. E The ability to machine plate faces up to a maximum 1,000 x 1,000 mm and a maximum thickness of 80 mm is yet another major advantage. For machining purposes, these can be positioned upright into the base frame.

CONTROL AND PROGRAMMING SOFTWARE

Professional, well-organized, and user-friendly: the HEIDENHAIN TNC 620 user interface.

The 15” TFT color flatscreen displays all information needed for programming, operating, and controlling the machine.Its user-friendly functionality is characterized by program sets, instructions, graphics support for entering programs, easily understandable symbols, and much more. The outstanding properties of the end-to-end digital concept guarantee maximum accuracy and surface finishes, even at high feed rates and high total system uptime. Storage media or display devices are directly and conveniently linked to the operator panel by the USB 2.0 interface.

For even greater convenience, we additionally offer optional programming software.

RÖDER PFZ 4000 CNC PROFILE MILLING CENTER

EVEN GREATER CAPABILITIES – ADD-ON OPTIONS

TECHNICAL DATA

| PROFILE MILLING CENTER | PFZ 4000 CNC | |

|---|---|---|

| Max. x axis working range | 4.000 | mm |

| Max. y axis working range | 400 | mm |

| Max. z axis working range | 400 (600) | mm |

| Toolholder | SK 40 HSK 63 | |

| Main spindle speed | 8.000 | U/min |

| Main spindle output | 11 | kW |

| Main spindle torque | 90 | nM bei 40% ED |

| Rapid travel | 30.000 | mm/min |

| Drilling performance into S355 | 36 | mm |

| Tapping into S355 | M20 | |

| Milling performance into S355 at 40% ED | 400 | cm³/min |

| Repeatability | ± 0,05 | mm |

| Compressed air supply | 6 | bar |

| Max. electrical output | 28 | kW |

| Fuse, slow | 63 | A |

| Overall floorspace requirements for machine, L x W x H | 6.600 x 4.500 x 3.400 | mm |

| Workpiece positioning height | 850 | mm |

| Overall weight, approx. | 6.000 | kg |

| WerkzeugwechslerTool changer | Option | |

| Stations | 8 bzw. 20 | |

| Max. tool ø: | 100 | mm |

| Max. tool length | 270 | mm |

| Max. tool weight | 5 | kg |