LOWER YOUR MANUFACTURING AND SHOP FLOOR COSTS NOW.

röma CNC TORCH CUTTING SYSTEMS

THE DEADLINE IS BURNING UNDER YOUR FINGERNAILS –

YOUR CUSTOMER IS APPLYING PRESSURE AND

YOU ARE WAITING FOR URGENTLY NEEDED SHEETMETAL BLANKS

Never again….

Free yourself of your dependencies to suppliers and make your cuts inhouse going forward: Together with the latest generation of plasma technology, the röma CNC torch cutter gives you the ability to produce your sheet metal parts at the highest quality level – flexibly and cost-effectively.

We customize each röma torch cutter specifically to your application – as the customer, you therefore have full control over the design of your röma!

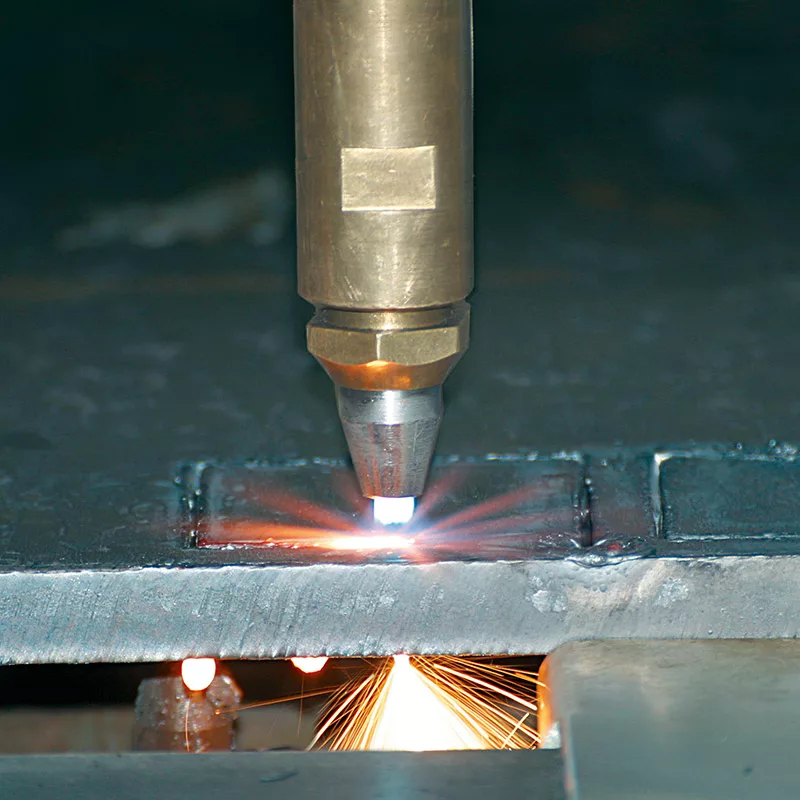

Plasma cutting

Stainless steel, aluminum, steel, nonferrous metals, and miscellaneous electrically conductive metals – including with painted surfaces – are readily cut using this technology.

The machined finishes are optimized with continuously controllable cutting current and distances. We offer the plasma cutting system in various performance classes to maximize cost efficiencies.

- Plasma cutting systems with Contour Cut technology by Kjellberg for the best possible cutting quality with respect to contour accuracy, rectangularity, and surface finish, including a further reduction of angular deviations on inner and outer contours, and very good repeatability and dimensional accuracy.

- HiFocus neo makes plasma cutting even more efficient by reducing process costs thanks to wear parts with long service lives and optimized technology.

- As a result, plasma cutting continues to be a cost-effective alternative to lasers since the procurement and operating costs are less than a third.

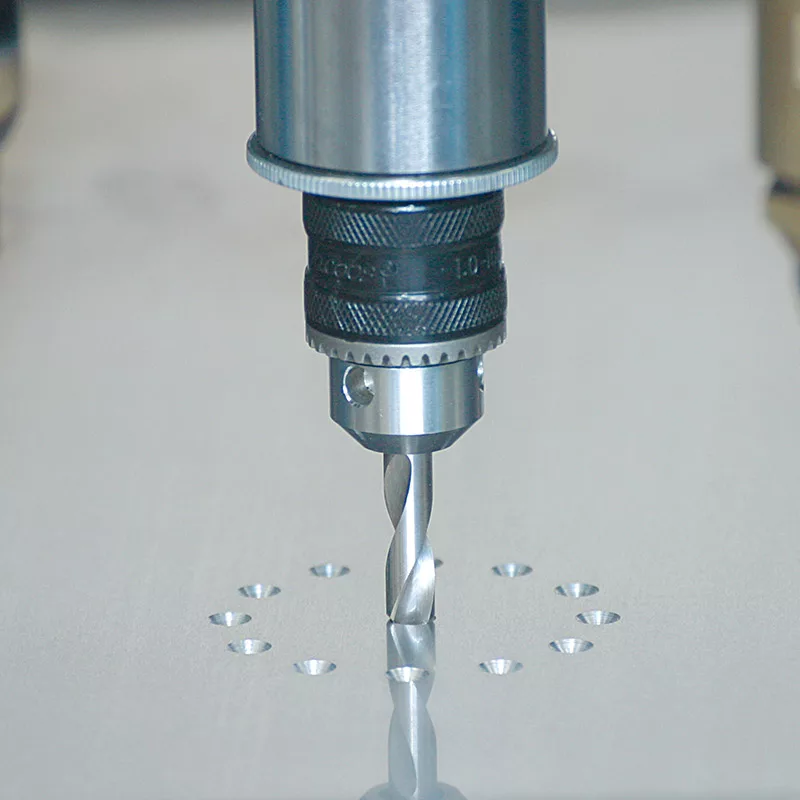

Pre-centering

A centering unit arranged in parallel to the torch head permits pre-centering parts on the machine itself. This makes time-consuming manual scoring a thing of the past. The sheet metal blank can be accurately processed in the operation.

This process can also be readily used to mark weldments.

Controls

One of the most important development objectives for the röma is its straightforward operability. It is the key for a short learning curve and effective operations.

In addition to the standard functions, the daily work is simplified by several details of the act/cut programming software favored by practitioners.

- Materials database for managing sheet metal panels with all key cutting parameters

- Automated sheet metal panel layouts

- Graphical part and sheet metal panel management